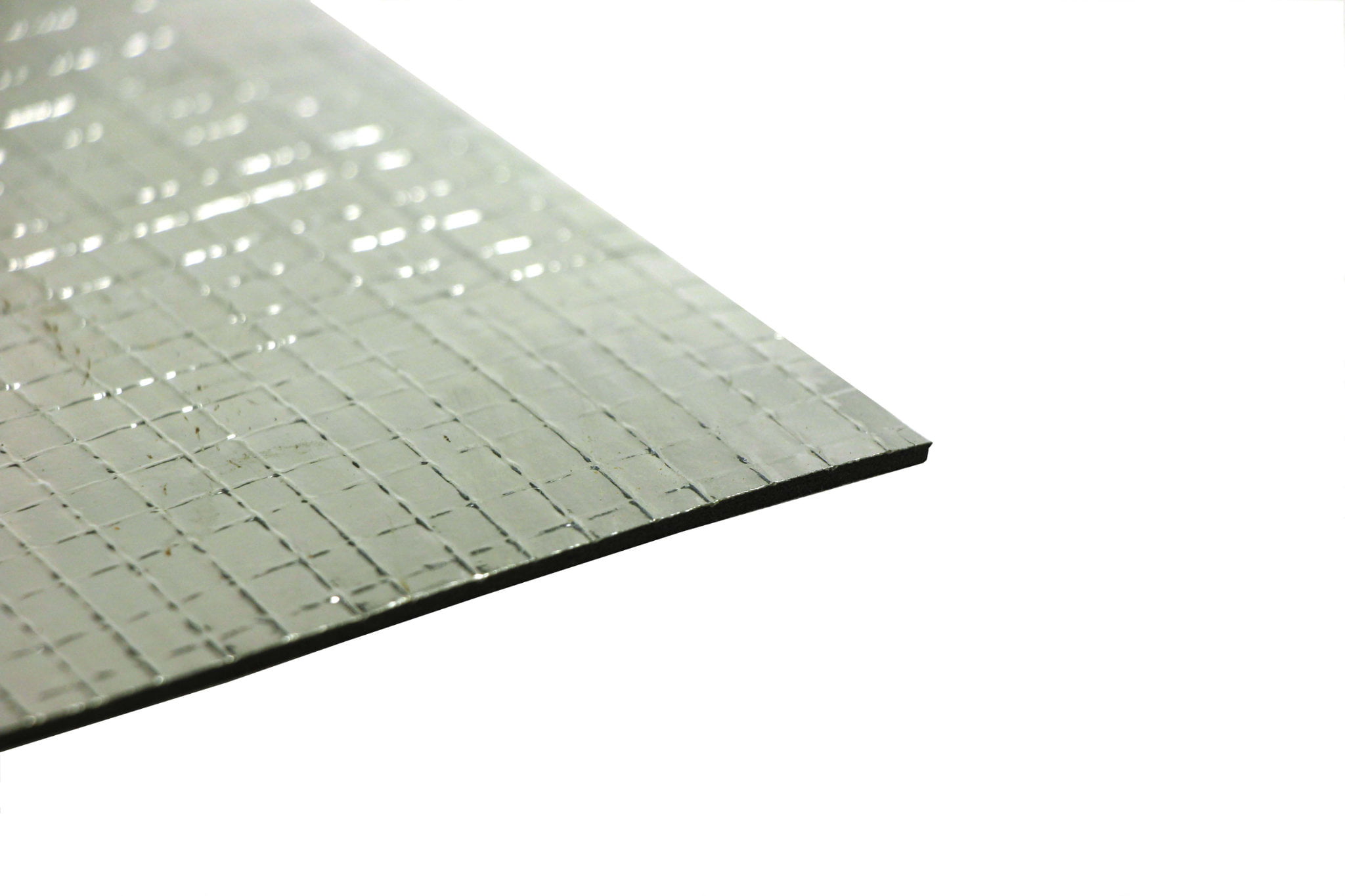

Acoustic foam is a sound absorptive media designed to reduce reverberation and amplification of airborne sound within an enclosed space. It is also used to absorb sound off hard surfaces. Depending upon the specific acoustical makeup of sound in a particular situation, foams are often faced with membranes and materials. This is done to ‘tune’ the foam to maximally absorb sound energy in specific sound frequency bands.

Versatile and flexible, acoustic foam has many applications for both industrial and architectural requirements. Most of our products work exceptionally well for in-plant, data processing equipment and even lawn and garden equipment noise control.

Many types of vehicles are an excellent fit for sound absorbing foam. Recreational vehicles & off-highway vehicles are great candidates for foam noise reduction. Interior linings of engine enclosures and hoods of trucks, busses and tractors will see a significant sound reduction with the addition of acoustic foam.

Architects use acoustic foam panels to absorb and reduce the sound in new builds and renovations. Whether it be an office space, recording studio, home studio or living room, where there is an enclosed space, foam can be an effective solution.

Typical applications:

Safety is of the utmost importance to us and our customers. Acoustic foam is also available in materials having even better fire resistant characteristics. These include melamine and micro-perforated ‘Millennium Metal’. This metal may be used to face metal sound panels to provide a fully fireproof, and weatherproof, sound absorptive surface.

Interior linings of engine enclosures & hoods of trucks, buses, tractors, construction equipment, compressors and generators.

In some cases, acoustic sound absorbing foam is not the best choice for sound absorption when a flexible barrier is needed. As noise and vibration control specialists, we offer first-rate solutions for our customers. This means providing the best flexible barrier acoustical treatment solution.

We stock flexible barrier materials made out of barium impregnated vinyl. The materials are about 1/8″ (3mm) thick and have a cross-sectional mass of 1#/square foot (4.88Kg/square meter). Most are fire resistant facing on one or both sides.

Some of our flexible barriers are reinforced with fibreglass cloth so that they can be hung as flexible ‘Acoustical Curtains’. Barriers should not be directly applied to sound generating surfaces. Doing so will reduce their effectiveness.

Vibra-Sonic Control stocks a wide range of acoustic products to address the ever-evolving variety of applications. From acoustic wall panels to sound dampening products, explore our products.

Also available with fire resistant reinforced metalized polyester film on 1 or 2 sides. -RP, -RP2.

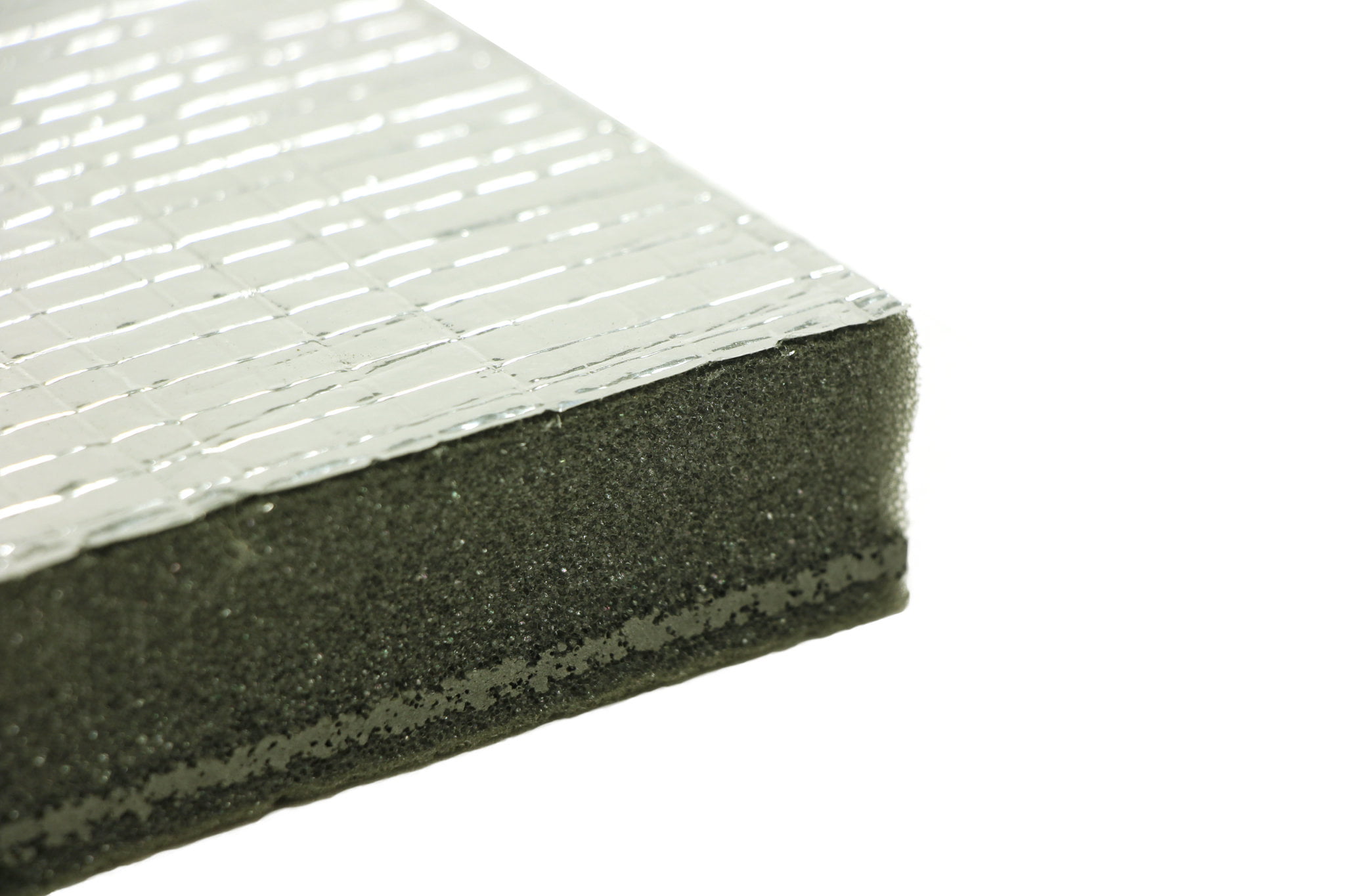

Our acoustically composite products are used to reduce reverberation within a space and increase the Sound Transmission Class (STC). This is done by sandwiching at least 1 layer of another soundproofing material to the original material. The combination of materials offers maximum sound blocking with each of the layers being critical and serving their own distinct purpose in reducing noise.

We carry six different types of acoustically composited products. They serve a variety of usages and are the first choice of plant engineers, design engineers and architects for a noise barrier solution in new construction, industrial and OEM.

Acoustically composited barriers are used in operator cabs, under heavy equipment, in marine engine room and for office equipment noise control. They are also used in truck hood baffles and for lawn & garden noise reduction plus a whole host of other uses. Explore our products to find which one best suits your needs or contact one of our Noise Control specialists to help you find the best fit.

Used for acoustical ‘lagging’, ‘single-product’ application where high & mid-range sound frequencies are predominant.

Available with fire resistant polyester film facing on 1 or 2 sides. – RP, – RP2

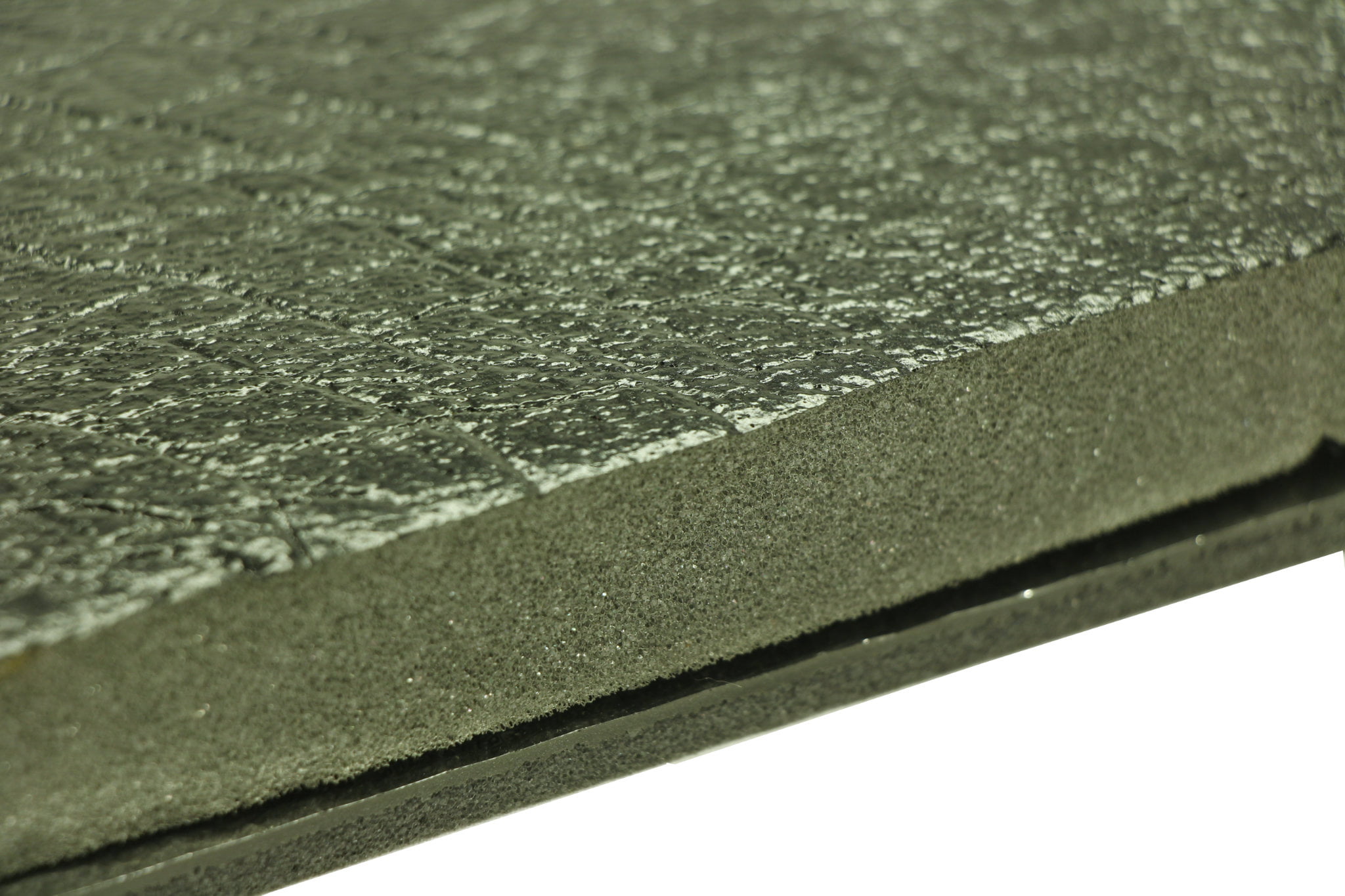

Same as 0-10NL-25 but with wear-resistant surface facing for low-traffic floor mat & equipment ‘Operator Cab’, side panel & ‘dog house’ barrier applications.

This product is similar to 0-10NL-25. Barrier is composited/sandwiched between a ‘wear resistant/carpet grain’ facing & decoupled. Closed cell neoprene below to reduce potential rusting of equipment’s floor pan in floor mat applications.

Typically used in Generator enclosure and Marine Engine Room applications where naturally aspirated diesel engines are involved.

Available fused to 2 lb/sft 10NL or with PSA1.

Used where engines are turbo-charged or where barriers and a mid – high frequency absorptive media are required. Also available with PSA1 adhesive backing.

A lightweight, weatherproof, relatively acoustically ‘clear’ wrap material for absorptive & absorptive/barrier materials and composites. Ideal for washable, cleanable, acoustical ‘baffle’ & panel applications.