Floating floors mitigate impact and airborne sound transfer and vibrations from impact. Where a traditional flooring system cannot meet the acoustic requirements of the project, floating floors are the answer. We are proud to represent Mason Floating Floors across Canada.

An acoustic floating floor is typically a secondary floor, made of concrete or wood, built above the main structure. A vibration isolator or underlay creates an air gap between the secondary floor and the main structure. The thickness of this air gap, the floating floor mass and the deflection of the isolators, isolate the structure. Increasing any of these will improve the performance of the floor.

Using rubber products in the system increases the level of damping and improves the IIC rating for impacts.

Vibra-Sonic carries a full line of isolation products with acoustic testing to meet your project requirements. From high impact sports facilities to yoga studios to theatres and much more.

Mason Jack Up Floors

Spring isolated jack up flooring systems are the most effective systems for reducing impact noise on the market.

A jack up floor system consists of a number of spring or LDS rubber mounts encased in a housing. The system forms a grid on the subfloor and is cast into the floating slab. The mounts interlock with the reinforcing. Once the concrete cures, specialty wrenches lift the floor to create air gaps ranging from 1 to 4 inches.

By casting the mounts in the slab we can have floating floors on springs while keeping the air gap down to as little as 1 inch. This eliminates the possibility of short circuiting. Which is when concrete leaks through a form and creates a hard contact back to the structure.

With jack up floating floor systems it is possible to design the system using mounts with several different capacities. Spacing between mounts to accommodate floors with high load areas are also a design possibility.

Formwork Floors Using Isolation Mounts

Our floating floor systems with separate isolation mounts provide the most flexibility for projects with complex loading needs. Formwork Floors have a wide array of different mount sizes and capacities.

This type of floor system is ideal for situations where:

No floor is too large or too small for this versatile system. Mounts come in thicknesses from 12 mm (1/2 “) to 102 mm (4’). They are designed for loads from 23 kgf (50 lbf) to 13,839 kgf (30510 lbf) per mount.

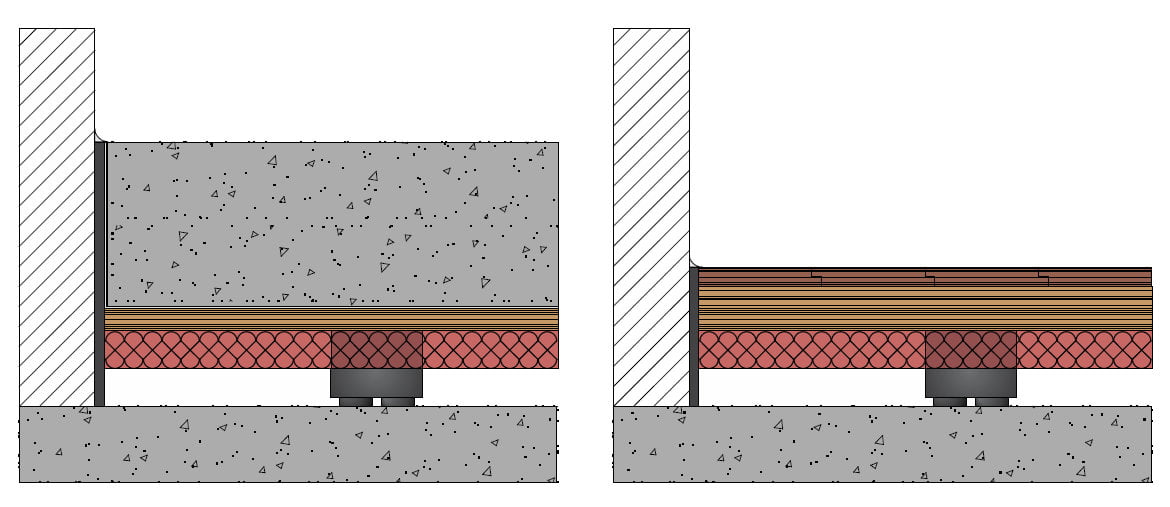

Panelized Wood Floor Systems With Built in Mounts And Insulation

Regupol’s panelized system offers excellent IIC ratings, along with the added benefit of fast to install all-in-one panels.

Panels come complete with OSB in 4 ft x 4 ft sections including rubber mounts and insulation that fills the air gap. This drastically reduces installation time.

Panelized wood floor systems can be used with:

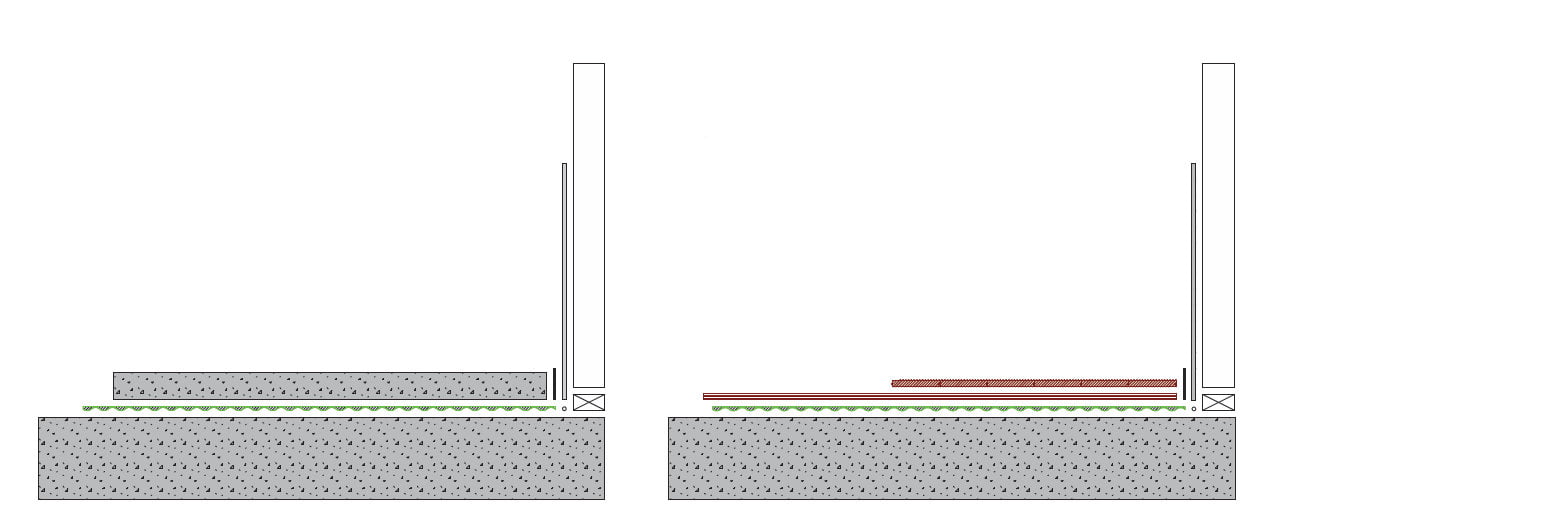

Isolation Mount Systems For Wood Floating Floors

When working on retrofits it is often the case that the structure was not designed for the load of a concrete slab. In these cases, wooden floating acoustic floor systems are a great solution.

These budget conscious systems use rubber LDS and spring mounts installed under 2×4 sleepers on their side and topped with plywood layers. Mason’s isolation mount systems are highly effective at reducing noise from impacts.

For increased STC values layers of wallboard or cement board can be layered in the wooden floor. Insulation can also be used to improve performance.

Underlay Systems For Concrete Topping Or Hardwood

Where impacts are a concern a quality underlay under your flooring system is a must. Vibra-Sonic carries a full line of high quality acoustic underlays.

Benefits of our high performance acoustic underlayment system:

Accessories

No matter which type of floating floor you choose for your project, Vibra-Sonic can provide all the accessories you need.

Looking for more information about Acoustic Floating Floor solutions? Contact us for technical advice, specification details, solution test data or a quote.

Recent Floating Floor Projects in Western Canada: